Double Block and Bleed (DBB) valves are critical components in many industrial applications, providing enhanced safety and isolation in critical processes. These valves offer a significant improvement over traditional single block valves by incorporating a unique design that minimizes the risk of leaks, enhances maintenance procedures, and improves overall system safety.

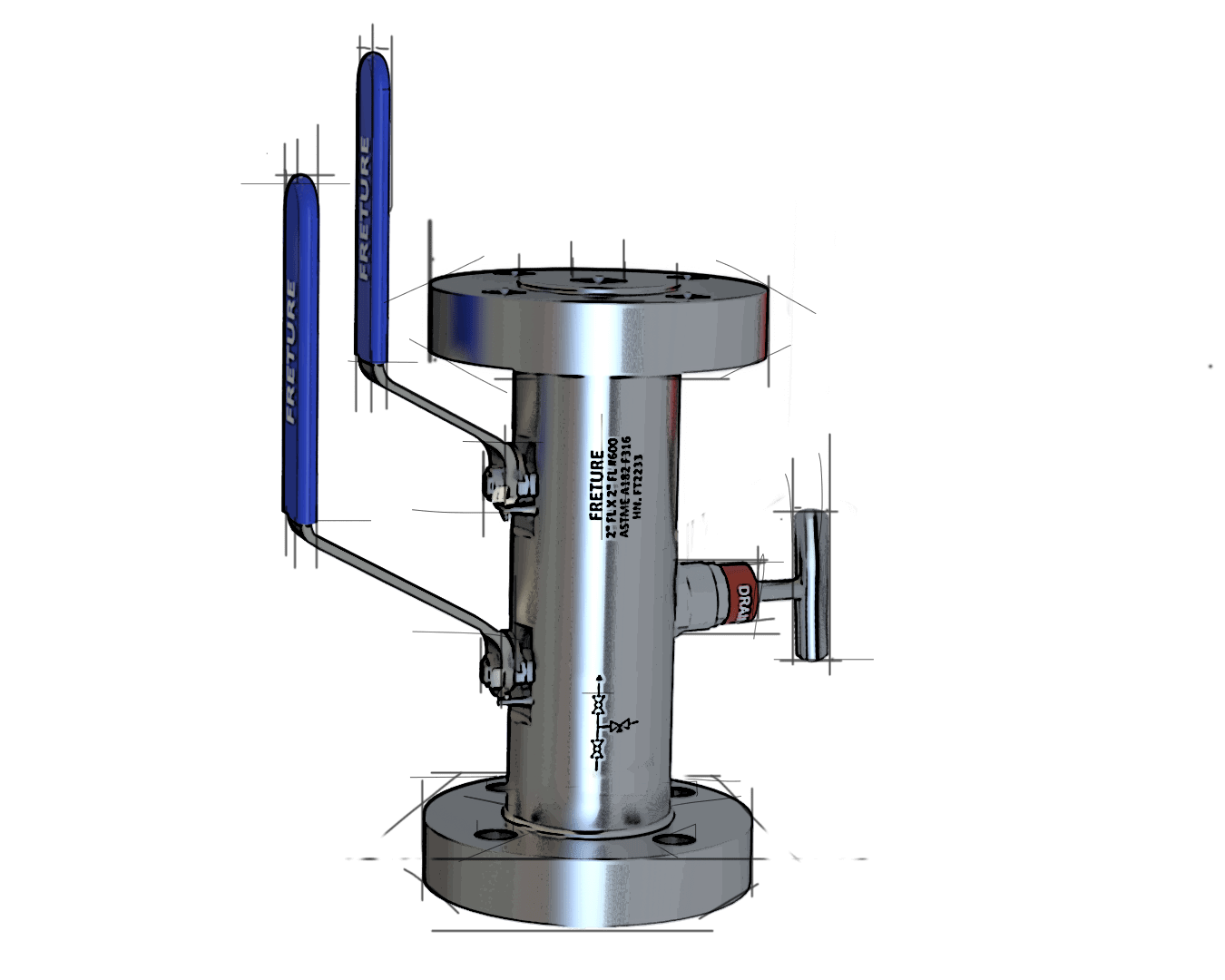

The DBB valve configuration typically includes two independent block valves and a bleed valve. The two block valves, strategically positioned along the pipeline, provide a double barrier for isolation. When both block valves are closed, the section of the pipeline between them is effectively isolated. The bleed valve, located between the two block valves, allows for the safe venting or draining of any residual fluid or gas trapped within the isolated section. This crucial feature significantly reduces the risk of leaks and potential hazards during maintenance or repair activities.

|

| Double Block and Bleed Valves |

By incorporating DBB valves, industries can significantly enhance safety and operational efficiency. These valves minimize the risk of leaks, spills, and potential environmental hazards. They facilitate safe and efficient maintenance procedures by isolating the affected section of the pipeline, allowing maintenance crews to work safely without disrupting the overall system operation. Moreover, DBB valves contribute to increased operational uptime by reducing the frequency and duration of unplanned shutdowns caused by leaks or equipment failures.

Beyond enhancing safety and operational efficiency, DBB valves offer several other key benefits:

- Improved Product Quality: In industries such as pharmaceuticals and food processing, DBB valves play a crucial role in maintaining product purity and preventing contamination. By isolating sections of the pipeline during maintenance or cleaning procedures, DBB valves minimize the risk of cross-contamination and ensure the integrity of the final product.

- Environmental Protection: By minimizing the risk of leaks and spills, DBB valves contribute to environmental protection and reduce the impact on surrounding ecosystems.

- Regulatory Compliance: DBB valves help ensure compliance with stringent environmental regulations and safety standards, such as those related to the handling and storage of hazardous materials.

Freture Techno is a leading DBB Valves manufacturer in India. We specialize in designing and manufacturing high-quality DBB valves that meet the stringent demands of various industries. Our commitment to quality, innovation, and customer satisfaction ensures that you receive reliable and durable valves for your critical applications.

By choosing Freture Techno, you gain access to a comprehensive range of DBB valve solutions, backed by expert support and a commitment to customer success. Our team of engineers can assist you in selecting the optimal DBB valve for your specific application, considering factors such as pressure, temperature, fluid properties, and safety requirements.

No comments:

Post a Comment