Double Block and Bleed (DBB) valves have become an essential part of industries that demand high levels of safety and operational efficiency. These valves are designed to provide isolation of critical systems, ensuring zero leakage and facilitating maintenance, inspection, or repair without disrupting the main process. From oil and gas to chemical processing, DBB valves are synonymous with reliability, safety, and precision.

In this article, we delve deep into the world of DBB valves, exploring their types, applications, and technical details, and why they are indispensable for modern industries.

What Are Double Block and Bleed Valves?

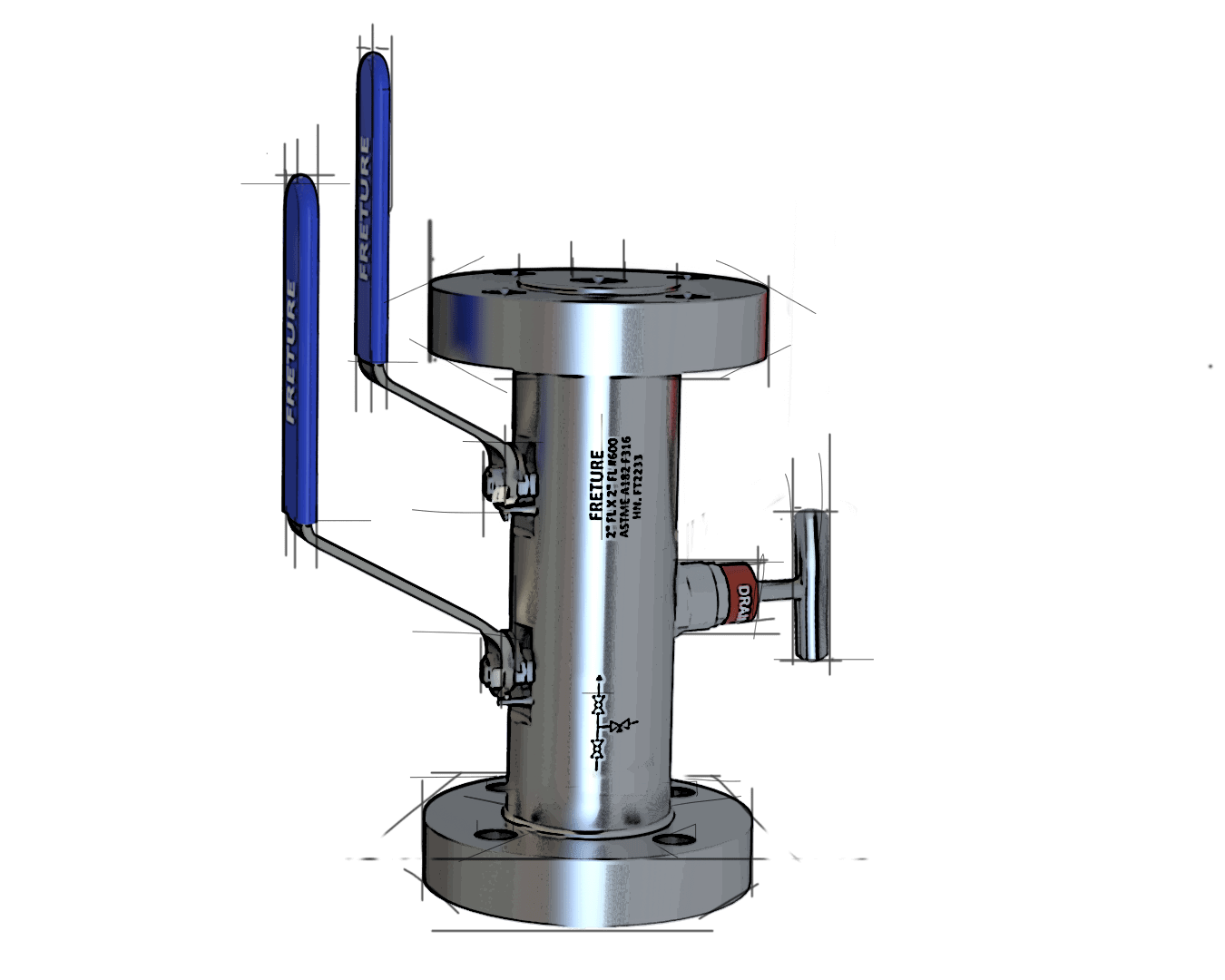

DBB valves are a type of valve arrangement designed to achieve a secure isolation system. They feature two in-line isolation valves (blocks) with a bleed valve positioned between them. The purpose of the bleed valve is to allow pressure release from the cavity between the two block valves, ensuring complete isolation and preventing any risk of leakage.

This design enhances safety by:

- Preventing cross-contamination between systems.

- Allowing safe maintenance and testing procedures.

- Providing a means to confirm the integrity of the isolation.

Key Features of DBB Valves

- Compact Design: Combines multiple valve functions into a single unit.

- Leak Tightness: Ensures zero leakage from the system.

- Ease of Maintenance: Reduces downtime during maintenance activities.

- Enhanced Safety: Prevents mixing of hazardous fluids, ensuring operational safety.

- Compliance: Meets international safety and quality standards, such as API 6D and ASME B16.34.

Types of Valves Under the DBB Category

Several types of valves fall under the DBB category, each catering to specific industrial needs. Below is an in-depth look at the major types:

1. Ball-Type DBB Valves

These are the most common type of DBB valves, offering excellent sealing properties and reliability. The ball valve mechanism allows precise control of flow and ensures tight shutoff.

- Applications: Oil and gas pipelines, chemical processing plants, and refinery systems.

- Materials: Stainless steel, carbon steel, and duplex steel.

- Pressure Range: Typically suitable for high-pressure applications up to 10,000 psi.

2. Needle-Type DBB Valves

Needle-type DBB valves feature a fine-threaded spindle for precise flow regulation and isolation. These valves are ideal for small-bore systems and instrumentation lines.

- Applications: Instrumentation systems, pressure monitoring, and flow control.

- Materials: Stainless steel and alloy steel.

- Features: Compact design and superior accuracy.

3. Monoflange DBB Valves

Monoflange valves integrate multiple valves into a single compact unit, reducing weight and installation time. They offer both double block and bleed functionality within a smaller footprint.

- Applications: Offshore platforms, FPSOs, and chemical injection systems.

- Benefits: Reduced space requirements, easy installation, and fewer potential leak points.

4. Plug-Type DBB Valves

These valves use a cylindrical or tapered plug to control flow and provide isolation. Plug-type DBB valves are known for their robust sealing and high durability.

- Applications: Oil and gas separation units and high-temperature environments.

- Materials: Nickel alloys, stainless steel, and carbon steel.

- Features: High temperature and pressure tolerance.

5. Gate-Type DBB Valves

Gate-type DBB valves utilize a sliding gate mechanism to isolate flow. These valves are suitable for applications requiring tight shutoff and high flow capacity.

- Applications: Petrochemical plants, LNG systems, and power plants.

- Advantages: Low-pressure drop and reliable isolation.

Applications of DBB Valves

DBB valves are indispensable in industries where safety and efficiency are paramount. Below are some of their major applications:

- Oil and Gas: Used in pipelines, separators, and offshore platforms to ensure leak-proof isolation and facilitate safe maintenance.

- Chemical Processing: Prevent cross-contamination between reactive or hazardous chemicals.

- Power Generation: Ensure the integrity of critical systems such as steam and gas turbines.

- Pharmaceutical and Food Industries: Provide sanitary isolation in pure water and process fluid systems.

- Refineries: Allow safe isolation and testing of pipeline segments.

Advantages of Using DBB Valves

Space and Weight Reduction: A single DBB valve replaces multiple traditional valves, saving installation space and reducing weight.

- Enhanced Operational Safety: Dual isolation reduces the risk of system failure.

- Cost Efficiency: Minimizes maintenance costs and system downtime.

- Reliable Testing: Allows for accurate pressure testing and system integrity checks.

- Technical Specifications

- End Connections: Flanged, threaded, or socket-weld.

- Size Range: From 1/2 inch to 36 inches or more, depending on the application.

- Pressure Ratings: ANSI Class 150 to 2500 or higher.

- Temperature Range: -50°C to 400°C, depending on the material.

- Standards: Compliant with API, ASME, and ISO standards.

Why Choose Freture Techno Pvt. Ltd. for DBB Valves?

Freture Techno Pvt. Ltd. stands at the forefront of industrial valve manufacturing, offering an extensive range of high-performance Double Block and Bleed Valves. With a commitment to quality, innovation, and customer satisfaction, we provide:

- Customizable Solutions: Tailored to meet your specific requirements.

- Stringent Quality Control: Ensures compliance with global standards.

- Expertise and Experience: Backed by years of industry expertise.

- Global Reach: Catering to industries worldwide with reliable and timely delivery.

In conclusion, DBB valves play a critical role in ensuring operational safety and efficiency across industries. With their ability to provide secure isolation and leak-proof performance, they are a valuable investment for any system requiring high reliability.

For premium-quality Double Block and Bleed Valves, trust Freture Techno Pvt. Ltd., a leading manufacturer in India dedicated to delivering innovative solutions for your industrial needs.