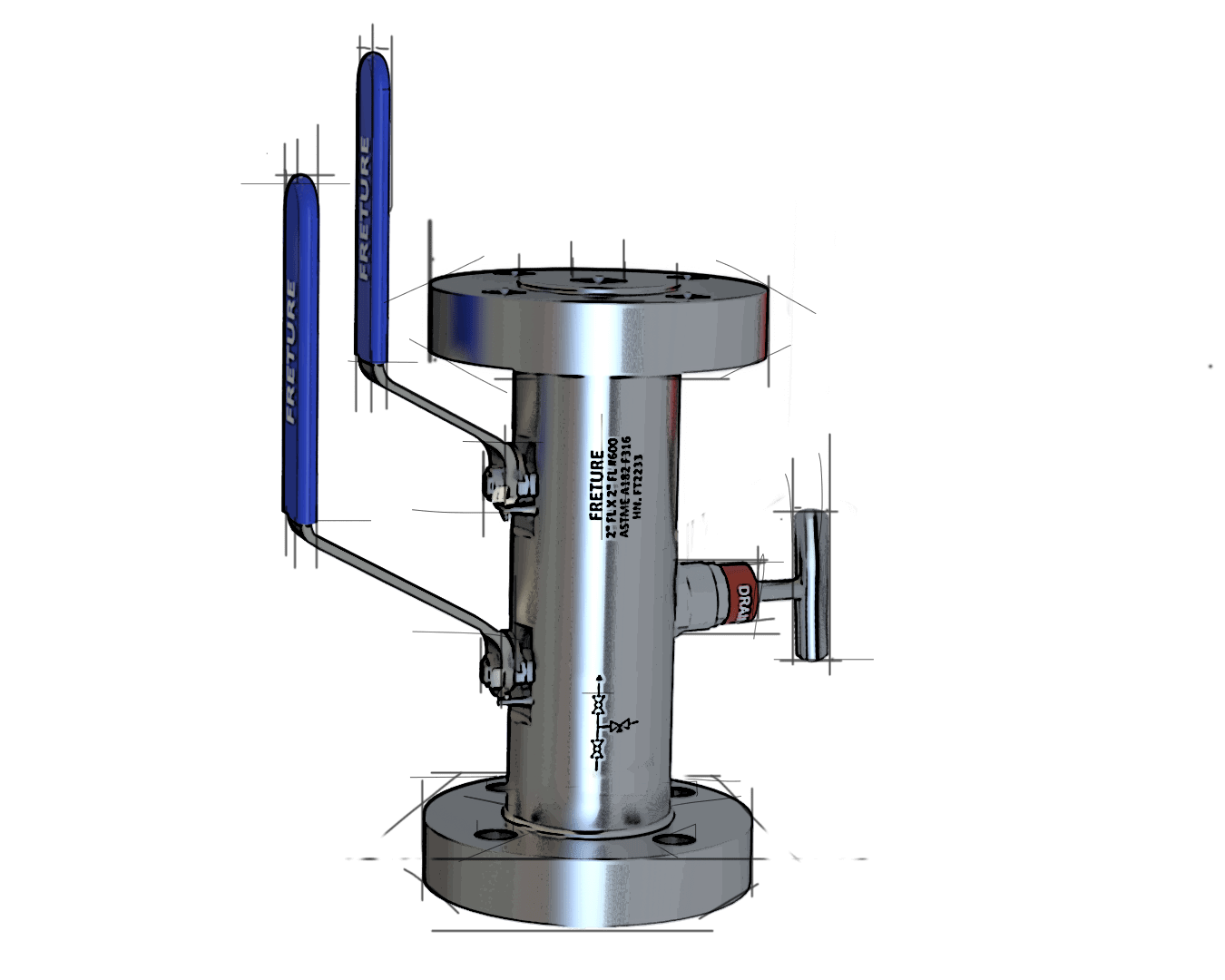

Double Block & Bleed (DBB) valves are specialized isolation valves combining two seating elements and an intermediate bleed port in a single body. By providing positive isolation and safe venting of trapped media, Double Block and Bleed Valves protect personnel, equipment, and the environment in demanding applications.

What Are Double Block & Bleed (DBB) Valves?

A DBB valve integrates two independent shut-off elements—typically balls or plugs—plus a bleed (vent) port located between them. When both isolation elements are closed, the cavity between them can be safely depressurized or sampled via the bleed. Variants include:

-

Integral DBB: all components in one body for minimal footprint

-

Tandem DBB: two separate valves with a shared bleed line

-

Dual-ball DBB: two balls in series for high-integrity shutoff

This design eliminates the need for multiple separate valves and piping, reducing leak paths and simplifying maintenance.

Key Industries & Applications

Oil & Gas Upstream

In wellheads and flow-control skids, DBB valves isolate tubing and casing for wireline operations. Before servicing, operators close both isolation elements and vent the intermediate cavity to ensure no hydrocarbons can escape.

Refining & Petrochemicals

DBB valves on high-pressure reactors and catalyst-loading lines enable safe loading and unloading without depressurizing the entire system. For instance, in hydrocracker feed manifolds, the bleed port verifies seal integrity before removing reactor heads.

LNG & Cryogenic Plants

Cold-box maintenance requires isolation of cryogenic lines carrying liquefied gases. DBB valves with cryo-rated seats and low-temperature alloys prevent inadvertent boil-off releases during purge and service operations.

Power Generation

Steam-turbine bypass and maintenance lines deploy DBB valves to isolate high-pressure steam. Operators use the bleed to verify upstream isolation before opening adjacent equipment, reducing the risk of unexpected live-steam exposure.

Chemical & Pharmaceutical

In processes handling toxic or ultra-pure fluids—such as anhydrous ammonia or API-grade solvents—DBB valves ensure zero cross-contamination. The ability to vent or sample between seats supports quality control and fugitive emissions compliance.

How DBB Valves Enhance Safety & Efficiency

-

Positive Isolation: Two independent seats provide double assurance against fluid passage, critical during maintenance or instrument calibration.

-

Built-in Bleed Port: Allows safe depressurization, sampling, or purging of trapped media, verifying seat integrity before work begins.

-

Fugitive Emission Control: With bellows-sealed stems and compliance to EPA and ISO 15848 standards, DBB valves minimize leaks of toxic or greenhouse gases.

-

Reduced Downtime: Simplified isolation and venting accelerate turnaround schedules, avoiding full-system depressurization and its associated hazards.

Selection & Best Practices

-

Material Choices: Stainless steel (SS 316/316L) for general service; duplex or Monel® for chloride-rich or sour environments.

-

Pressure/Temperature Ratings: Select valves certified to API 6D (pipeline service) and NACE MR0175 for H₂S resistance; verify seat materials for operating temperatures.

-

Installation Tips:

-

Position bleed piping to safe collection points

-

Include test ports for cavity pressure checks

-

Ensure adequate space for full stroke and maintenance

-

Conclusion & Call to Action

By combining dual isolation elements with a venting function, double block and bleed valves deliver unparalleled safety, integrity, and operational efficiency. Whether in oil & gas, petrochemicals, power, or pharmaceuticals, DBB valves are indispensable process safety valves for critical isolation.

Contact our experts today to discuss engineered DBB solutions tailored to your industry’s toughest challenges