In industrial piping, safety and reliability aren’t optional — they’re mandatory. A Double Block and Bleed (DBB) valve is a compact, three-valve arrangement that provides two independent isolation points in series (two block valves) with a bleed path between them. When you need to service a live line, DBB lets you prove zero pressure between the blocks before maintenance begins, reducing the risk of leaks, spills, and accidents.

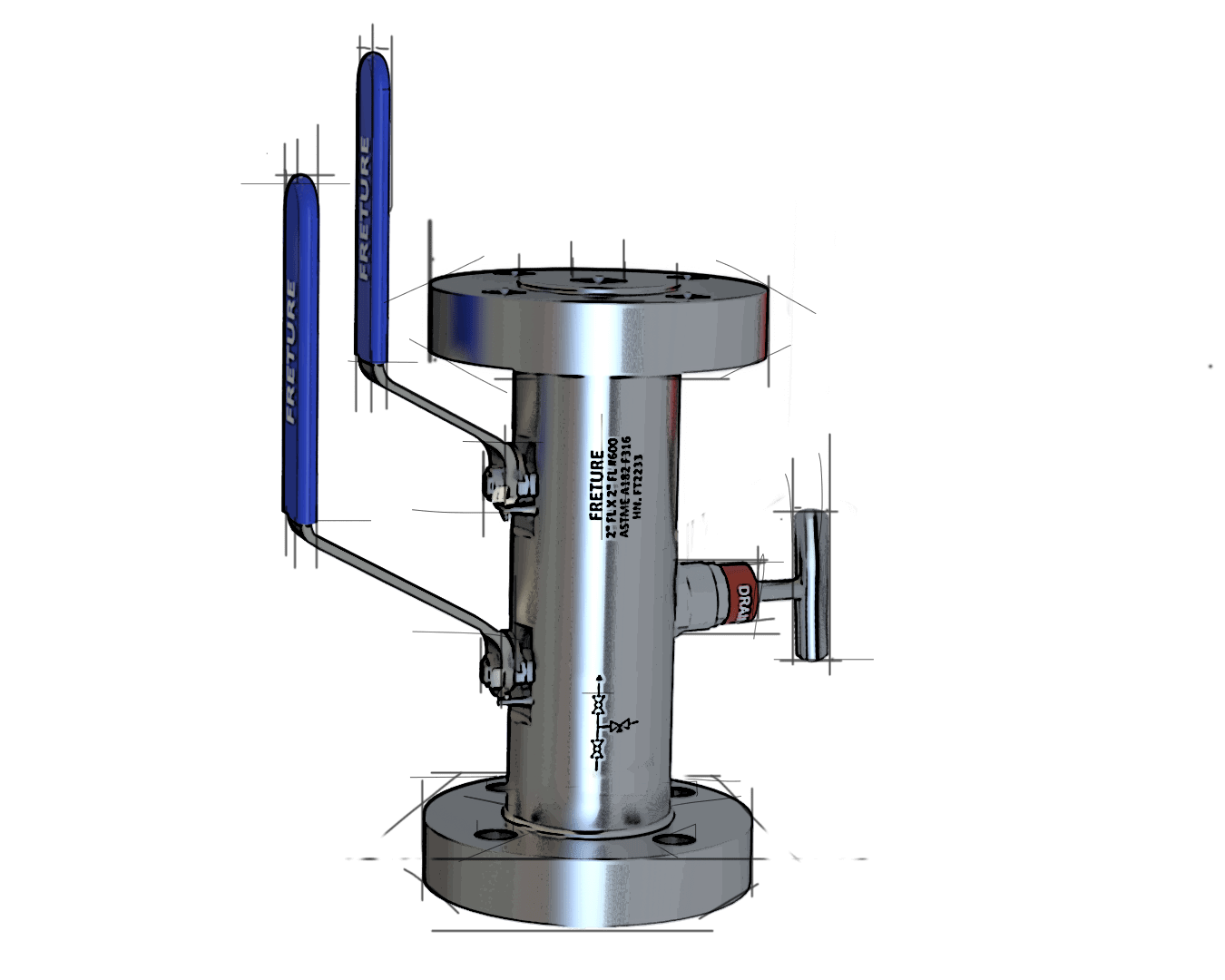

What is a DBB valve? A DBB valve is typically two seating surfaces in one assembly (two isolation valves) plus a bleed valve between them. API 6D defines the DBB concept as a single valve with two seating surfaces that seals against pressure from both ends, with a means to vent or bleed the cavity between the seats. This is contrasted with double isolation-and-bleed (DIB), where each seating surface seals against pressure from a single source, sometimes in one or both directions. Understanding this distinction helps engineers choose the right device for the job.

How DBB works in practice The standard DBB sequence emphasizes positive isolation and inter-valve verification:

Close the upstream isolation valve first.

Open the bleed valve to drain or vent the cavity between the two block valves and confirm no pressure exists.

Close the downstream isolation valve to complete the isolation.

When work is done, repressurize in reverse, first opening the downstream valve, then the bleed, and finally the upstream valve. This creates a controlled, verifiable path to resume operation. This sequence is described across industry guidance and process-control primers.

Benefits that matter for safety and cost

Enhanced safety: two barriers plus a bleed path provide verifiable zero-energy isolation, especially important for hazardous or high-pressure services.

Space, weight, and cost savings: DBB configurations can replace multiple separate valves, reducing footprint and installation complexity.

Reduced leak paths and maintenance time: integrated or compact DBB designs minimize potential leak points and simplify maintenance workflows.

How to choose and use a DBB valve

Consider your service: high-risk, toxic, or high-pressure lines favor DBB for positive isolation.

Decide on configuration: integral (one-piece) DBB versus a manifold of separate block and bleed valves; both aim to reduce weight and leak paths.

Verify standards: API 6D definitions and BVAA guidance help distinguish DBB from DIB and ensure compliance.

Conclusion A correctly implemented DBB valve arrangement delivers safer, faster, and more reliable isolation for maintenance, sampling, and process shutdowns. By understanding the DBB concept, operational sequence, and the trade-offs between integrated vs. multi-valve configurations, engineers can choose the right solution for their system and regulatory needs.